Before quoting a label job, distributors should ask specific questions to understand exactly what clients need and avoid costly missteps. Gathering the right details up front helps ensure accuracy, customer satisfaction, and efficient production. Here are ten key questions to ask and why each matters:

1. What are you using the labels for?

Why it matters:

Knowing the labels’ end-use determines the material, adhesive strength, and printing method required, ensuring the labels perform as expected.

2. What size and shape do the labels need to be?

Why it matters:

Size and shape impact die-cutting needs, tooling costs, and printing capabilities, directly affecting the pricing and feasibility.

3. Are there specific color matches or brand guidelines?

Why it matters:

Precise color matching ensures brand consistency, which is essential for customer satisfaction and brand integrity.

4. What quantity do you need, and are there multiple label versions?

Why it matters:

Understanding quantities and variations influences pricing, production scheduling, and the potential for cost savings with higher volumes.

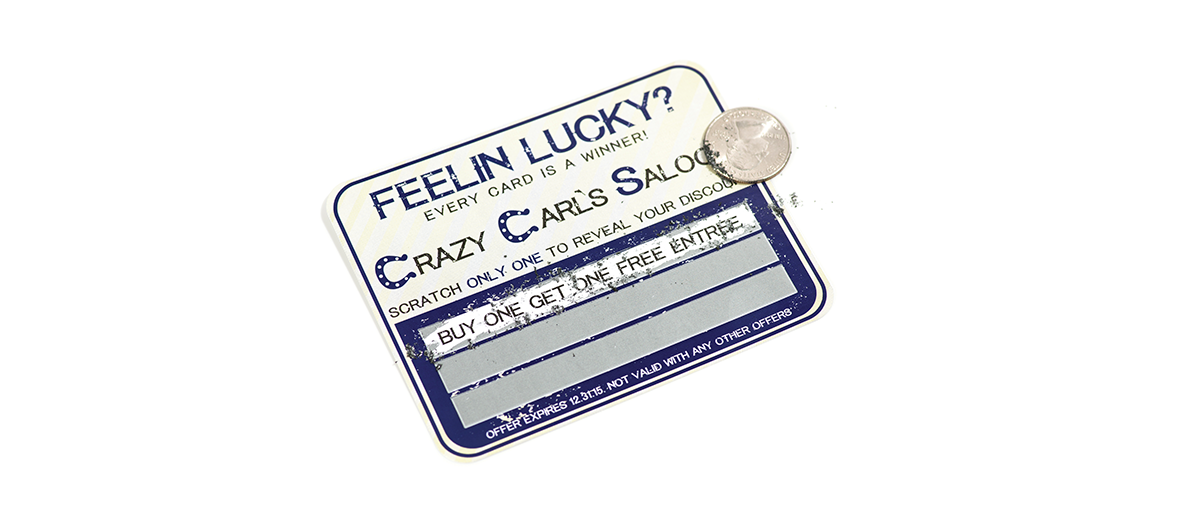

5. What surfaces will the labels be applied to?

Why it matters:

Surface type (glass, plastic, metal, rough, or smooth) determines adhesive selection, ensuring labels adhere properly and last as intended.

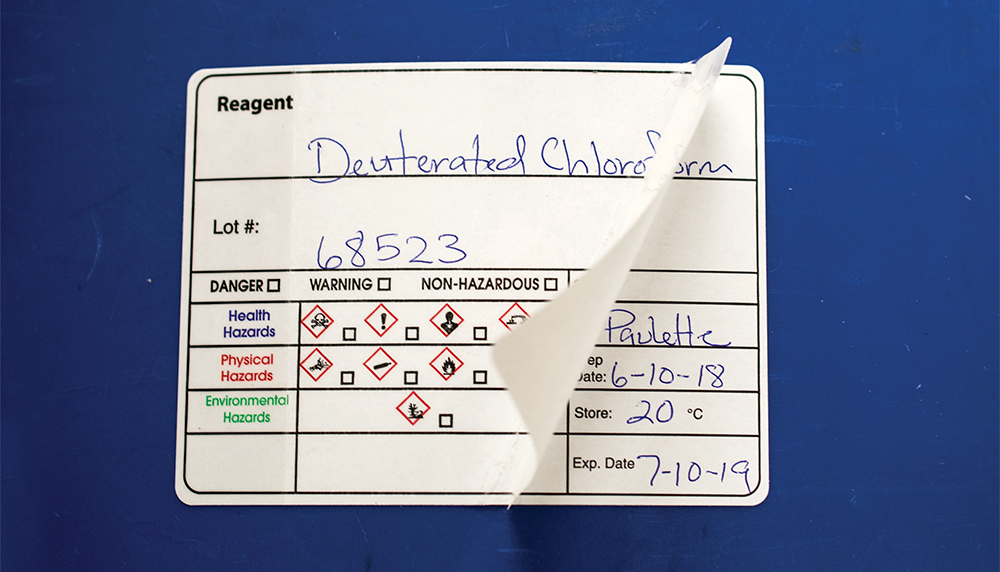

6. What environmental conditions will the labels face?

Why it matters:

Conditions such as moisture, chemicals, UV exposure, or extreme temperatures affect material and adhesive durability, impacting label performance.

7. Do you require a special finish or protective coating?

Why it matters:

Special finishes (lamination, varnishes) affect label durability, appearance, and functionality, influencing client satisfaction and longevity.

8. Are there regulatory requirements or certifications needed?

Why it matters:

Industries like food, pharmaceuticals, and chemicals have specific regulations affecting label materials and printing standards, crucial for compliance.

9. Will labels include variable data like barcodes, QR codes, or numbering?

Why it matters:

Variable data affects the choice of printing technology, equipment capabilities, and the complexity of the job, influencing cost and turnaround time.

10. What turnaround time do you require?

Why it matters:

Identifying delivery expectations upfront ensures you can meet deadlines and prioritize jobs effectively, leading to better client relationships.

Get Accurate Quotes Every Time

By asking these targeted questions, you’ll gather essential details to deliver precise, competitive quotes and produce labels that perfectly match client requirements. If you’re looking for reliable, versatile labeling solutions, check out our selection of wholesale custom labels.

FAQs about Quoting Label Jobs

What information is essential for quoting a label job?

Key details include label purpose, size, material, quantity, colors, surface application, environmental factors, special finishes, regulatory needs, and deadlines.

How do environmental factors affect label choices?

Environmental conditions like humidity, chemicals, UV exposure, and temperature extremes dictate the choice of materials and adhesives for optimal label durability.

Why does the application surface matter?

Different surfaces require specific adhesives for proper adhesion, performance, and longevity, directly affecting client satisfaction.

Are higher quantities always cheaper per label?

Yes, higher quantities typically reduce per-label costs due to economies of scale in production and materials, saving clients money.

How do special finishes affect label pricing?

Finishes like lamination or varnishing increase durability but may raise costs. It’s important to balance client needs with budget considerations.