Digital label printing gives your customers the chance to get up close and personal with their labels. How many know, or appreciate, what this means to their label-creating potential?

For most, there likely are at least a few gaps in their knowledge of digital label printing’s personalized capabilities. These gaps are your sales opportunities. Let’s look at several ways that the personalizing power of digital label printing can benefit them, and in turn you.

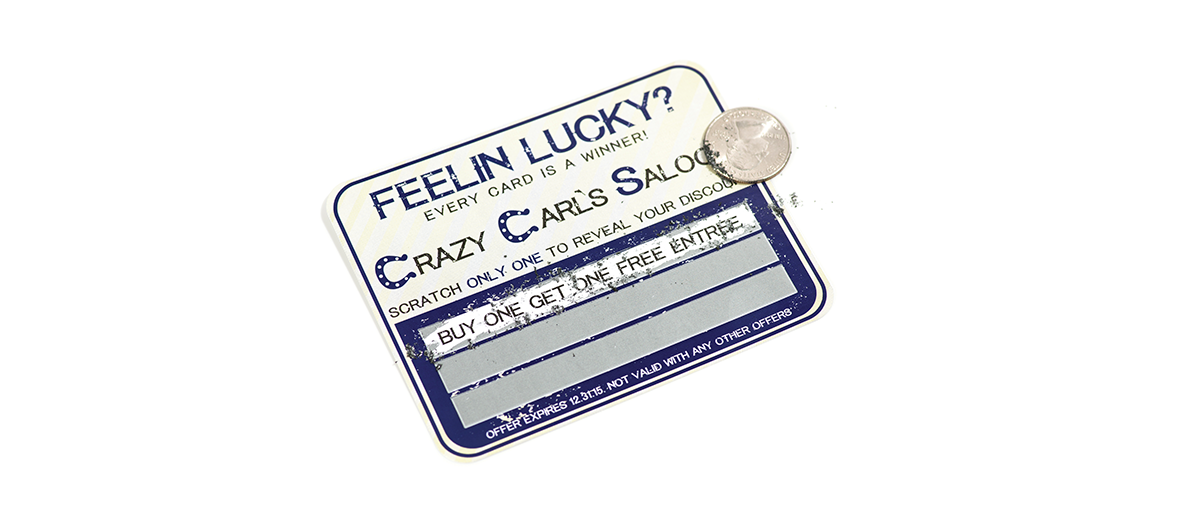

Variable data is a mainstay for those needing numbering, barcodes and other sequential products. But how about developing a different graphic for each label? Particularly for companies dealing in lower volumes, this can be an incredible branding tool. Imagine one of your customers promoting their product’s uniqueness with an approach like, “It’s not just what’s in the bottle that sets us apart, it’s what’s on the bottle that makes you unique—your one-of-a-kind look.” With an attractive graphic, this also can become a “collector’s” piece—driving future orders as much for the unique bottle as the product itself.

Laser die-cutting equipment enables customers to provide a die line and our team can produce the desired custom die cut with no die charges. Usually the words “custom” and “no cost” don’t sync up on one process, but they do here.

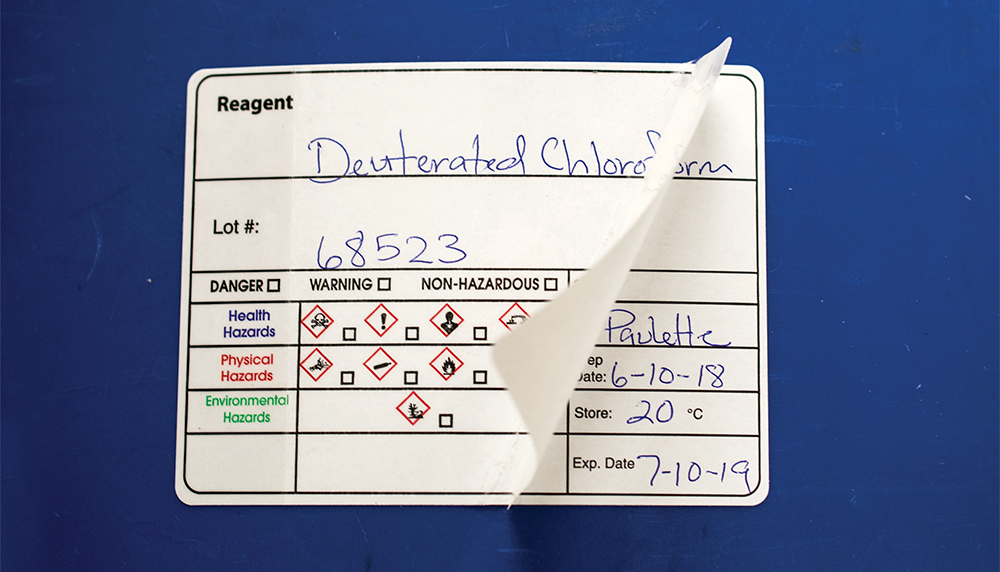

Advanced color control tools allow color matches up to 90% of the Pantone Matching System. Coupled with a large range of digital media including films, synthetics and metallics and diverse coating options, your customers can get their custom color palette matched to both previous and new looks along with their personal brand of special finishing effects.

And, of course, digital label printing affords your customers delivery on highly personalized schedules (a/k/a “a screaming hurry”). Nine digital presses, including CMYK sheetfed, CMYK inkjet, and Expanded Gamut Roll capabilities, enable Discount Labels to get even highly personalized jobs turned around quickly to meet even the most pressing deadlines. A front-end automation system reinforces order processing and prepress efficiencies to streamline production and increase digital capacity as well.