- Adhesive

- Back – Adhesive is on the back of the label. If this label is being applied to a window, it will go on the outside of the window.

- Face – Adhesive is on the front of the label. If this label is being applied to a window, it will go on the inside of the window.

- Backside Printing

- Copy is printed on the liner of the label. This printing method is used to offer coupons or convey additional information to the customer.

- Bleed

- Ink extends to the edge of the label.

- Cores

- The inner diameter of a roll of labels. The standard finishing is coreless. 1” and 3” cardboard cores are available upon request. For additional sizes, see a sales associate.

- Emboss

- An image is pressed into the material to raise it above the normal level of the material.

- Extended Life Durable Decals

- Labels are manufactured to withstand harsh environments and rugged applications. Durable for 3-4 years.

- Four Color Process Printing

- The use of four ink colors (Cyan, Magenta, Yellow and Black) to create an image, such as a photograph.

- Lamination:

- Clear plastic coating that provides extra durability

- Matte – Can be written on

- Textured – Used to add texture to labels

- Shiny –Shiny coating

- Clear plastic coating that provides extra durability

- Machine Applied

- These labels are set up to meet the requirements of the machine that will be applying them. You will often need to confirm core size, rewind direction and maximum outside size.

- Opaque

- A darkened adhesive used as a “cover up”. Restricts copy from showing through the face stock.

- Perforation

- Liner is perforated between the labels allowing them to be easily separated.

- Pressure Sensitive Label

- A self-adhesive label which is easily applied to a surface by pressure.

- Repositionable Label

- Patterned adhesive that allows the label to be applied and reapplied to almost any surface. Removes cleanly leaving no residue.

- Reverse

- Image is created by the label stock color showing through the ink coverage.

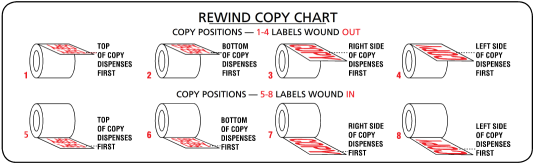

- Rewind direction

- Single

- Labels are individually cut and stacked.

- Spot Color Printing

- The use of one ink for each color printed. Separate plates are required for each ink color being applied to a material.

- Static Cling

- Labels have no adhesive and adhere to glass or other smooth surfaces with static electricity.

- Square Cut

- Also known as Butt Cut or Kiss Cut. These labels are cut exactly to size with no excess liner around the label. Order any size from ¼” x ¼” to 12” x 24”.

- Tint

- Label stock is “flood coated” to match a specific color.

- Varnishes:

- Liquid coatings that are printed onto the label surface

- UV – UV-cured varnish, very high gloss

- Water based – Protects label from slight moisture, less durable than UV varnish

- Matte – Dull varnish, can be written on

- Spot – Only part of the label is varnished

- Liquid coatings that are printed onto the label surface

- Weatherproof Labels

- These labels can withstand heat, cold, water and sunlight for up to 1-1/2 years.