Label printing can feel overwhelming, especially when you encounter industry-specific terminology. As a distributor, understanding these terms is essential to ensuring you receive the right product for your clients. This guide breaks down the most common label printing terms, making them easy to understand and apply in your work.

Common Label Printing Terms

Bleed

In label printing, bleed refers to the area of your label design that extends beyond the cut line. This extra space ensures that your design covers the entire label with no unprinted edges showing after trimming.

- Why It Matters: Bleed is essential for achieving a professional, edge-to-edge look on your labels. Without it, you risk ending up with a visible white border around your design.

- Practical Tip: Always extend your design by about 1/8 inch (0.125 inches) beyond the label’s cut line to account for bleed.

Die-Cutting

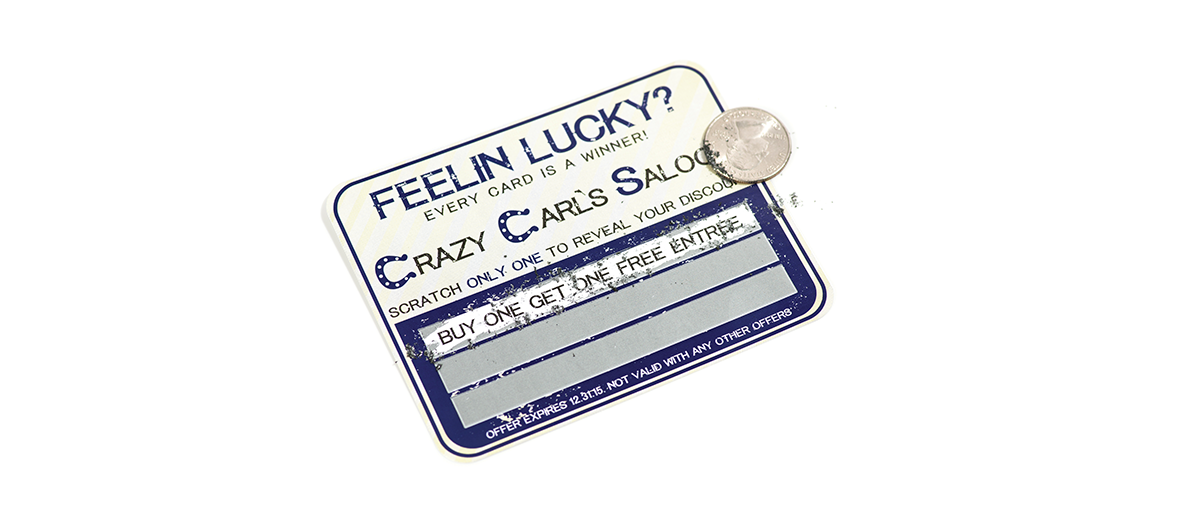

Die-cutting is the process of cutting labels into specific shapes using a metal die. This method allows for the creation of custom shapes, such as rounded corners or intricate designs that make your labels stand out.

- Why It Matters: Die-cutting enables you to create labels that align with your brand or product’s unique shape, enhancing their visual appeal.

- Practical Tip: Consider the shape and size of your labels early in the design process to ensure your die-cutting needs are met efficiently.

Material and Adhesive Terms

Facestock

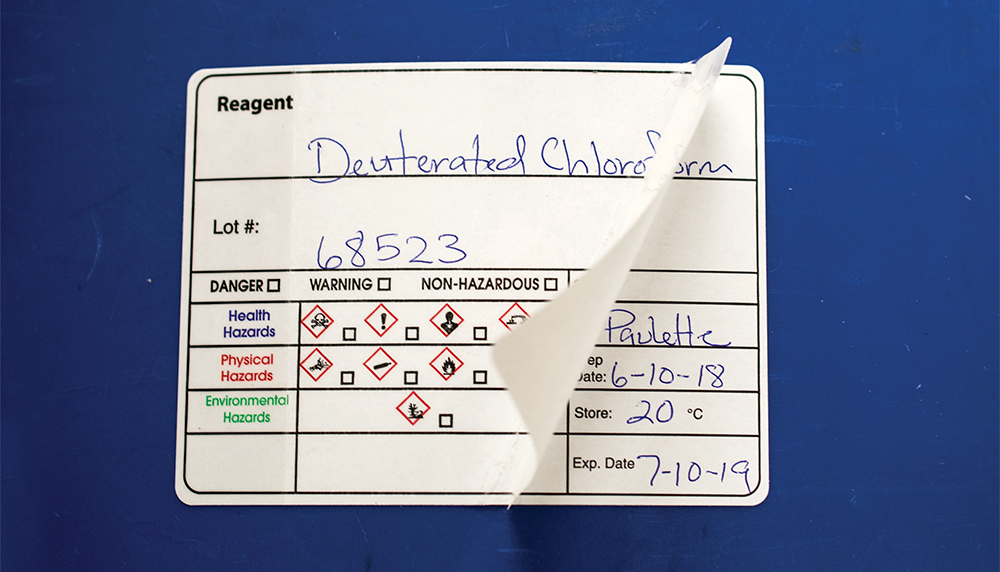

Facestock is the top layer of the label where your design is printed. It’s the visible and touchable part of the label, made from materials like paper, vinyl, or polyester. Choosing the right facestock is crucial for both appearance and durability.

- Why It Matters: Different facestocks offer different benefits. For example, paper facestock is suitable for cost-effective labels, while polyester is ideal for heavy-duty applications.

- Practical Tip: Consider the environment in which the label will be used (indoor, outdoor, exposure to chemicals) when selecting your facestock material.

Liner

The liner is the paper or plastic backing that protects the adhesive until the label is ready to be applied. Once the label is peeled off, the liner is typically discarded.

- Why It Matters: The liner ensures that your labels remain in good condition until application. Different liners are designed for various types of adhesives and application methods.

- Practical Tip: Thicker liners are easier to peel off, making them ideal for hand-applied labels, while thinner liners work better with machine applications.

Printing Techniques

Flexographic Printing

Flexographic printing (often shortened to flexo) is a high-speed printing process that uses flexible printing plates to transfer ink onto the label material. This method is ideal for large runs of labels that require consistent quality and quick turnaround times.

- Why It Matters: Flexographic printing is efficient and cost-effective for large-volume orders, especially when using spot colors or simple designs.

- Practical Tip: Flexo printing is great for producing labels with solid colors and bold designs, but it might not be the best choice for labels with detailed images or gradients.

Digital Printing

Digital printing is the go-to method for short-run labels and designs that require lots of color detail. Unlike flexo, digital printing doesn’t require plates, allowing for faster setup and greater flexibility, particularly for smaller orders or designs with variable data.

Why It Matters: Digital printing offers high-resolution results with vibrant colors, making it ideal for labels that need photographic quality or unique barcodes.

Practical Tip: While you don’t choose between digital and flexographic printing, rest assured that our team will select the best method based on your order’s specifications, previous runs, and workflow efficiency.

Label Finishes and Effects

Lamination (Matte, Textured, Shiny)

Lamination is a protective layer applied to the label’s surface to protect it from scratches, moisture, and other environmental factors. Different finishes—matte, textured, or shiny—add varying aesthetic qualities to your labels.

- Matte: Offers a non-reflective finish that gives labels a sophisticated, subdued look.

- Textured: Adds a tactile feel to your labels, enhancing the sensory experience.

- Shiny: Provides a high-gloss finish that makes colors pop and adds a polished look.

Practical Tip: Choose matte for a modern, understated look, textured for an interactive feel, and shiny for a vibrant, eye-catching appearance.

Embossing and Foil Stamping

Embossing and foil stamping are techniques that add depth and a premium look to your labels.

- Embossing: This technique raises certain parts of your label, creating a 3D effect that adds texture and visual interest.

- Foil Stamping: Adds a metallic sheen to specific parts of your label, often used for logos, borders, or text.

Practical Tip: Combining embossing and foil stamping can create a label that stands out, adding a tactile and visual element that attracts attention.

FAQs

What is the difference between digital and flexographic printing?

Digital printing is best for short runs and highly detailed designs, offering quick setup times and flexibility. Flexographic printing is more cost-effective for large runs and is ideal for simple designs with solid colors. Each has its strengths depending on your label’s needs.

How do I choose the right adhesive for my labels?

Choosing the right adhesive depends on the surface you’re applying the label to and the environment it will be exposed to. For temporary labels, opt for removable adhesives. For long-term or outdoor use, go with a permanent adhesive that can withstand elements like moisture and heat.

If you’re unsure which adhesive is best for your specific application, don’t hesitate to contact us. Our team at Discount Labels is ready to help you find the perfect solution for your labeling needs.

What are the benefits of using specialty finishes on labels?

Specialty finishes like lamination, embossing, and foil stamping not only protect your labels but also enhance their appearance. These finishes can make your labels more durable and visually appealing, helping them stand out on the shelf or in a catalog.

Summing it up

Understanding label printing terminology doesn’t have to be daunting. With a solid grasp of these common terms, you can make informed decisions and communicate more effectively with your clients and suppliers.

Whether you’re discussing bleed, selecting the right facestock, or understanding how we decide between digital and flexographic printing, you’ll be equipped to handle your label projects with confidence.

Contact Discount Labels today to get started on your next custom label project!